Having the right backing paper is critical to your label project success

If you are just doing a very small run, hand applied label, then your backing paper probably doesn’t matter. If you are using any type of automated application, or you may want to use automated application in the future, then the backing paper is critical.

Begin with the End in Mind

Knowing exactly how you will get the labels onto your box, bag, or bottle will help you select the right backing paper. If you have a table top label machine, or a bottling line, your equipment should have a preferred type of backing paper. If you use a contract (mobile) bottler, then it is especially important to have a clear understanding of the proper backing paper for their equipment so you have a smooth, productive day of bottling.

What are my Options?

These are the choices for backing paper – 40# (white) backing, 44# (brown) backing, and 1.2 mil PET (clear) backing.

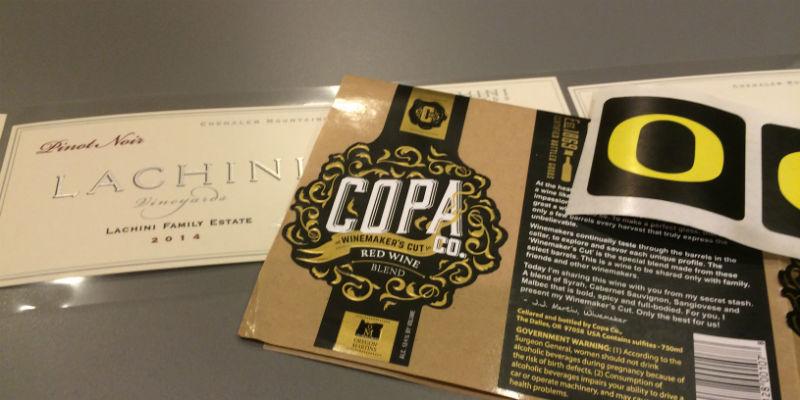

- 40# White – this is most common for food labels and some beverage applications. It is thin and light and works pretty well in most applications. ** Shown above on the Oregon Ducks label. NOTE – their is also a 50# White backing that is very common in the Craft Beer market – it looks just like the 40# above, but more durable.

- 44# PK (poly coated Kraft) Brown – this is most popular in the wine industry. This is slightly thicker and the heavy poly coating can help the labels release better on a bottling line. ** Shown above on the Copa Di Vino label.

- 1.2 mil Clear PET – this polyester liner is thinner and has higher tensile strength than the other two. Some mobile bottlers insist on this option for all wine labels. ** Shown above on the Lachini wine label.

But wait, there’s more!

You can’t just pick the label backing by itself – it isn’t just something you pick off the menu. Label materials consist of a face stock (the label itself), adhesive (the glue) and the backing (the label liner we are discussing). Unfortunately, not every face stock is available with every adhesive and every liner – you will generally have to pick and chose between recommended combinations unless you are placing a very, very large label order that will justify a custom material run.

Finally – don’t forget the Cutting Die

Besides compatibility with the application equipment, your label stock (and especially the backing), need to be compatible with the cutting die that will be cutting the labels to their final shape. Cutting dies are precision machined to cut to a particular depth – these are some times called ‘kiss cutting’ dies because they just cut through the face (label itself) and should just barely touch (or kiss) the backing paper. If the cutting die cuts too deep, you will have serious problems on the application line. Of course if it doesn’t cut deep enough, you will not have finished labels in the proper shape – so having a die that is compatible with the material you select is critical.

For this reason, our cutting dies are all specifically calibrated or the backing material they cut – you can’t pick a proper die until you have your material selected.

Sound Confusing?

If all these options make your head hurt, don’t worry. We do this every day and we are happy to help. We can break it down for you and take the mystery out of label materials, backing paper, and cutting dies. You concentrate on making your sauce, wine, fudge, or beer – we will handle the labels.